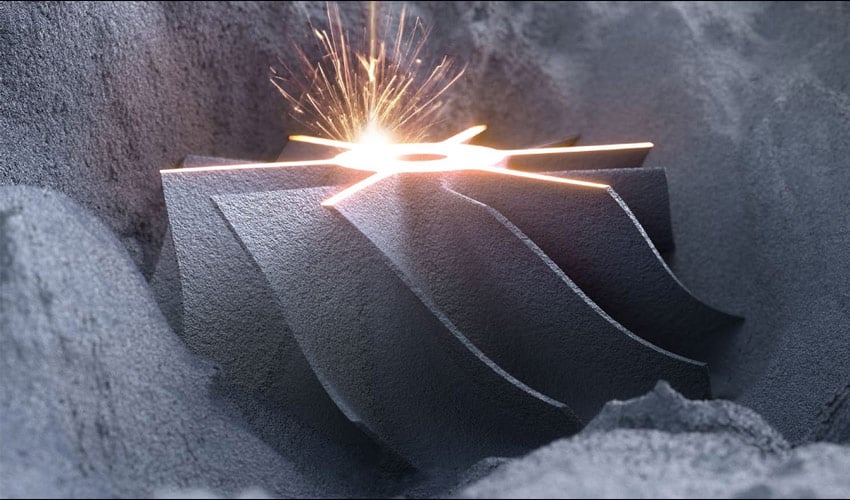

The printing technology of selective laser melting

In selective laser melting, fine metal powder is melted layer by layer using a laser. The properties of the technology:

- Minimum wall thickness: 1 mm.

- Lettering and surface details: min. 0.5 mm.

- Minimum diameter of drill holes: 2 mm.

- Complete powder removal cannot be guaranteed for very small holes, long channels and small cavities.

- In this process, support structures are used for overhangs. These support structures are removed during production. The underlying surface is of a lower quality than the remaining surfaces.

- Components are aligned to optimise installation space.

- Please make an individual enquiry for special requirements

- Tolerance: DIN ISO2768-1m.